It doesn't take much to get me doing research on a subject of interest. In this case, it started out with the color scheme of the F4U-2 (see

http://tailhooktopics.blogspot.com/2013/06/f4u-2-color-scheme.html) and segued to antennas. Unfortunately, I wasn't able to nail it all down to my satisfaction but at least I have some progress to report. Much of this has already been noted by Don Fenton on Hyperscale.

First, the F4U-2s were converted from some of the earliest production F4U-1s. In fact, the very first production F4U-1 was modified to be the prototype. As a result, some pictures show early Corsair features like the 360-degree cowl flaps. They subsequently received many changes before they deployed in addition to the unique hardware needed for the night fighter mission and probably some while overseas in combat. However, there was at least one exception to the "standard" Corsair configuration: the stall strip on the right wing leading edge doesn't appear on the deployed pictures of the VMF(N)-532 and VF(N)-101 airplanes.

And they might have had the taxi/landing light under the left wing, a feature on early F4Us and of benefit to a pilot flying at night from land bases:

As far as the cockpit goes, a three-inch diameter radar scope was added in the middle of the instrument panel directly under the gunsight, which was the original one with an integral reflector glass, and the bullet-resistant plate glass between the windscreen and gunsight was removed for improved visibility.

Obviously some of the instruments had to be rearranged, with the artificial horizon being moved to the left according to this mockup picture:

It looks to me like the artificial horizon was incorporated in a Sperry autopilot installation.

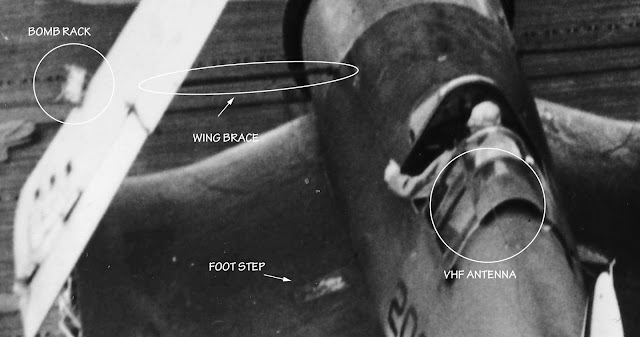

For some reason, the antenna mast was deleted and the bitter end of the wire antenna was terminated at the outboard end of the leading edge of the right horizontal stabilizer. A VHF radio was installed with its whip antenna on the turtleback mounted slightly left of centerline and angled left. An IFF whip antenna was mounted on the belly aft of the downward vision window. The radar altimeter required two identical antennas on the belly.

The radar altimeter antenna installation is one of the more confusing configuration details since these were at least initially mounted fore and aft of the downward vision window as shown here.

However, there don't seem to be any radar altimeter antennas in some pictures - they were probably only essential for carrier operations at night - and in others the two antennas are both mounted under the aft fuselage. My guess is that there were two alternatives (three when you count none being installed) as shown on this illustration along with other configuration details.

Some annotated pictures that might be helpful:

Note that the first picture is a VMF(N)-532 airplane as are all with 2XX side numbers. The second on is assigned to VF(N)-101, which provided detachments to

Enterprise and

Intrepid; these had one and low two-digit numbers. Pictures of the VF(N)-75 airplanes are scarce, as in I've seen one poor reproduction in a book.

Some F4U-2s had the armor added atop the rear of the canopy:

The biggest error in kits, including Tamiya's 1/48th F4U-2, is the radome. The fairing on the upper surface of the wing didn't taper in width as viewed from the top like subsequent wing-mounted radome installations. It didn't taper at all as it faired into the wing surface:

Don Fenton provided some guidance with respect to the Tamiya 1/48th F4U-2 kit in addition to what I've already noted above:

The 1/48 Tamiya F4U-1/2 kit has the outer wing panel fuel tank filler caps in the wrong position. Fill in existing and rescribe new ones same position but one panel line inboard. Add the handgrips to the caps if you want. And while you're at it, add the small vent tubes to underside of the wing. These go in the minute indention shown near the large rectangular hatch in the lower outer wing panel. These are characteristic of the wet wing Corsairs. Check page 23 D&S 55.

- Do not use the centerline fuel tank or Brewster bomb rack.

- Cockpit interior was painted black or Dull Dark Green, take your pick. The instrument cowl and interior of the windscreen was likely painted black.

- Use the salmon colored primer as you please for the wheel wells.

- Gear struts and the interior of the engine cowling likely remained Light Gray

- Paint over the downward vision window

For Dave Hansen's 1/32nd Tamiya build, see

http://forum.largescaleplanes.com/index.php?showtopic=56654&page=1

and/or

https://imodeler.com/2017/06/a-corsair-for-bob/

+unit+SKS+4500+X112A-3+NASWF.jpg)

.jpg)